Adventage

Precision comes from profession and responsibility

Broaching and Nick System

Using high hardness tungsten blade, the durability will be significantly improved.The depth of broaching and nick can be altered automatically by the software to meet different requirements.Thanks to the independent research and development, our multiunit broaching and nicking system will achieve 3 kinds of broachings and nicks(0.18-1mm) which is identified and controlled automatically by the software.

Notching System

For normal use, “bridges, miter-lip, straight cut”is performed by a multiple cartridge.The height of bridges and the size of miter-lip can be adjusted automatic by the software.Thanks to the smart design, our machines allow you to change over one multiple cartridge to another one for different rules and functions within minutes. In the event of wider special cartridge function, we customize the cartridges to produce perforating, cut/crease and hole. One tool can be applied to the cutting rule whose height ranges from 8mm to 12 mm or from 23-30mm,if rules’ bevel is same.

Bending System

Adopting sleeve bending system can produce different complicated angles quickly.High quality raw material of spare parts guarantee longer working life which will reduce the factory cost.Flatness can be adjusted quickly to be suitable to all kinds of rules.

Feeding System

Compare to other auto bending machines, the advantage of dual-screw feeding system: The speed and precision will be much higher than single-screw feeding system. It will not be influenced by the rule’s thickness and height.

Software System

Newly developed software can be support by Windows 10 operation system,Chinese-English language can be selected optionally by users.

Automatic Rule Elevator System

Independent six plates of automatic rule elevator whose height be adjusted by software. Smart safety protection can effectively avoid the accident.

Catalog

- ROTA BEND -

RotaProCut R-2080 Base model

Steel cutting Rule Diameter Range: 200~800mm

Steel cutting Rule Height Range: 21~27mm

Bridge Width: 10/13mm

Bridge Height: 10~18mm

Perforating Width: 2~13mm

Perforating Height: 0.5~6mm

Operation System: Windows 10

Data Input: DXF, DWG, Ai, CF2

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases 220V, 20A, 3KW,50/60Hz

Dimension & Weight of Machine: 1330x1130x1860mm 637KG

Dimension & Weight of Rule Elevator: 770x990x1200 166KG

RotaProCut R-2080 Base model

Marking system for bending

Perforating

Srtraight cut

Bridges

Rotary

Laser Crease till 8 pt

Straight Rotary

RotaBend-R2570

Steel cutting Rule Radius Range: 250~700mm

Steel cutting Rule&Crease Height Range: 23.8/28.8mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V, 20A3KW, 50/60Hz

Dimension & Weight of Machine: 1330x1130x1860mm 600KG

JHD-R2570 BASE MODEL

Bending

Perforating

Bridges

Rotary radial curved

Straight Rotary

Srtraight cut

- DIE BEND -

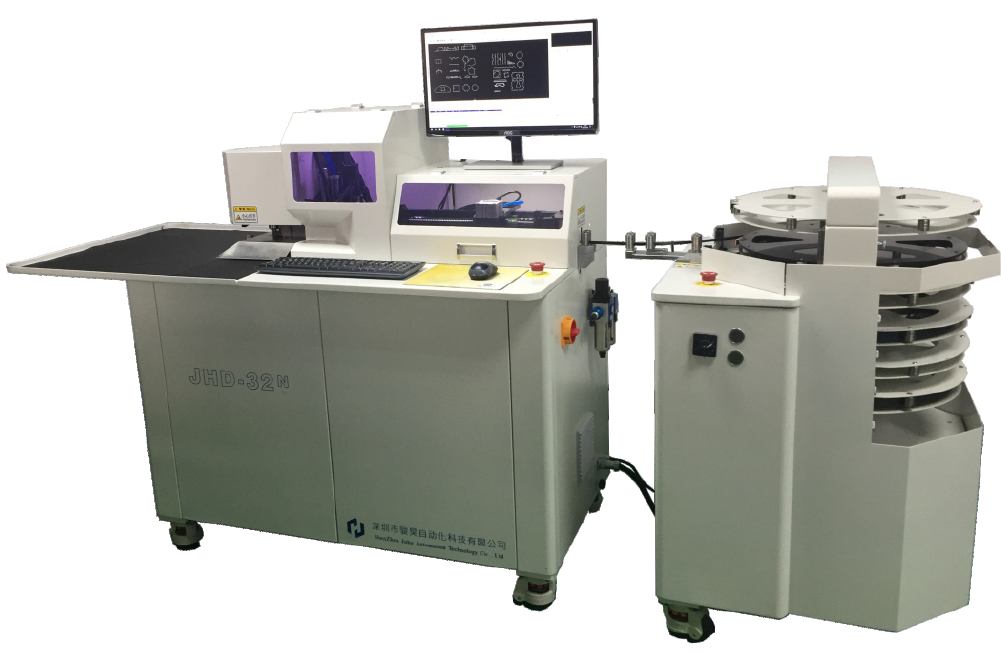

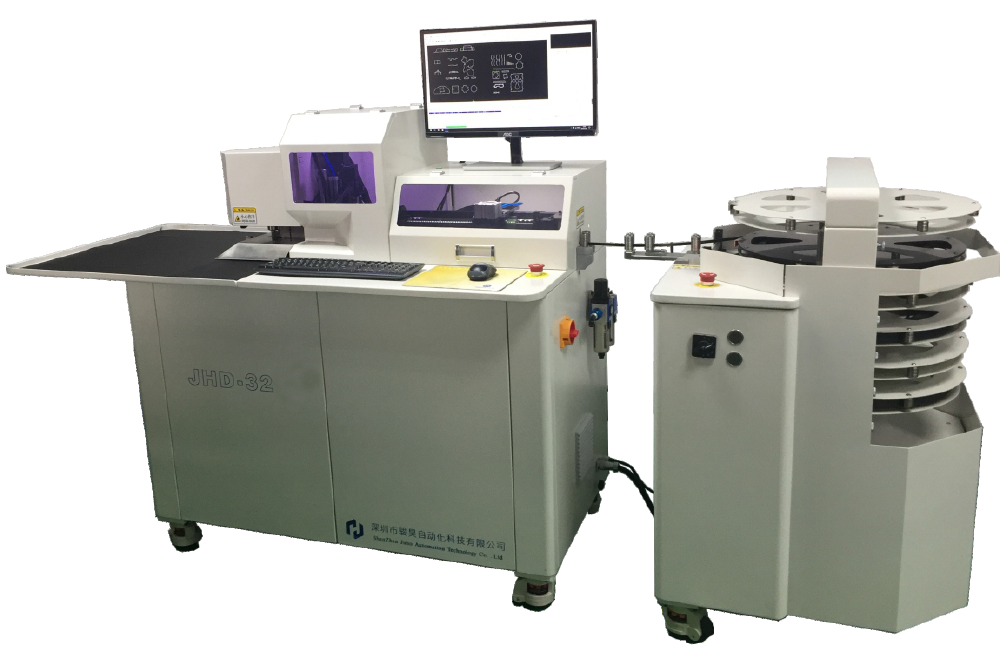

DieBend-32 / DieBend-32N

Steel cutting Rule Thickness Range: 0.45~1.07mm

Steel cutting Rule Height Range: 7~32mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases 220V, 20A3KW, 50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

Dimension & Weight of Rule Elevator: 700x900x1200mm 200KG

JHD-32 Base Model

Bending

Flat cut

Miter-lip

Bridges

JHD-32N Optional Model

Bending

Flat cut

Miter-lip

Nick

Bridges

Optional tools

OPTIONAL TOOLS

Perforating

Hole

DieBend-32B / DieBend-32BN

Steel cutting Rule Thickness Range: 0.45~1.07mm

Steel cutting Rule Height Range: 7~32mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

Dimension & Weight of Rule Elevator: 700x900x1200mm 200KG

JHD-32B Base Model

Bending

Flat cut

Miter-lip

Broaching

Bridges

JHD-32bN Optional Model

Bending

Flat cut

Miter-lip

Broaching

Bridges

Nick

Optional tools

OPTIONAL TOOLS

Perforating

Hole

DieBend-32C / DieBend-32CN

Steel cutting Rule Thickness Range: 0.45~1.07mm

Steel cutting Rule Height Range: 7~32mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

Dimension & Weight of Rule Elevator: 700x900x1200mm 200KG

JHD-32C Base Model

Bending

Flat cut

Miter-lip

Srtraight cut

Bridges

JHD-32CN Optional Model

Bending

Flat cut

Miter-lip

Srtraight cut

Bridges

Nick

Optional tools

OPTIONAL TOOLS

Perforating

Hole

DieBend-32CB / DieBend-32CBN

Steel cutting Rule Thickness Range: 0.45~1.07mm

Steel cutting Rule Height Range: 7~32mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

Dimension & Weight of Rule Elevator: 700x900x1200mm 200KG

JHD-32CB Base Model

Bending

Flat cut

Broaching

Srtraight cut

Bridges

Miter-lip

JHD-32CBN Optional Model

Bending

Flat cut

Nick

Broaching

Srtraight cut

Bridges

Miter-lip

Optional tools

OPTIONAL TOOLS

Perforating

Hole

DieBend-32BN+ / DieBend-32CBN+

Steel cutting Rule Thickness Range: 0.45~1.07mm

Steel cutting Rule Height Range: 7~32mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

Dimension & Weight of Rule Elevator: 700x900x1200mm 200KG

JHD-32BN+ Base Model

Bending

Flat cut

Broaching

Nick

Bridges

Miter-lip

JHD-32CBN+ Optional Model

Bending

Flat cut

Nick

Broaching

Srtraight cut

Bridges

Miter-lip

Optional tools

OPTIONAL TOOLS

Perforating

Hole

DieBend-52C / DieBend-52CN

Steel cutting Rule Thickness Range: 0.71~1.42mm

Steel cutting Rule Height Range: 20~52mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

Dimension & Weight of Rule Elevator: 700x900x1200mm 200KG

JHD-52C Base Model

Bending

Flat cut

Srtraight cut

Miter-lip

Bridges

JHD-52CN Optional Model

Bending

Flat cut

Srtraight cut

Miter-lip

Bridges

Nick

Optional tools

OPTIONAL TOOLS

Perforating

Hole

Rotary

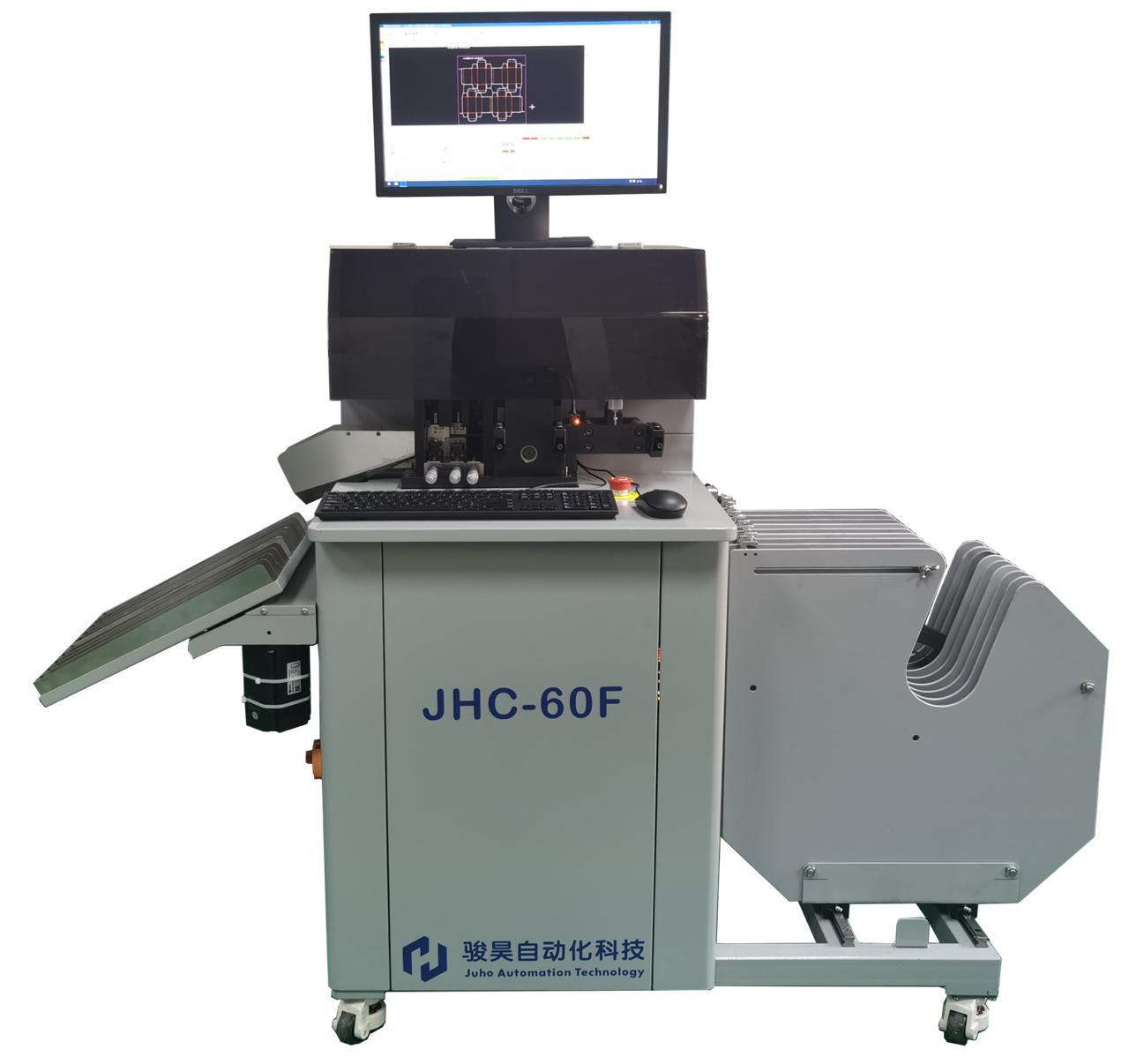

DieProCut-60 / DieProCut-60F

Steel cutting Rule Thickness Range: 0.45~1.42mm

Steel cutting Rule Height Range: 7~60mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

JHC-60 Base Model

Cutting rules/ Creasing rules

Optional tools

Perforating

Srtraight cut

Flat cut

Miter-lip

Bridges

Rotary

DieBend-50

Steel cutting Rule Thickness Range: 1.5~2.5mm

Steel cutting Rule Height Range: 20~52mm

Operation System: Windows 10

Data Input: DXF DWG

Compressed Air Supply: 1CFM at 6bars

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Machine: 2500x800x1600mm 429KG

JHD-50 Base Model

Bending

Twist

ARC-06 Rule Elevator

Steel cutting Rule Thickness Range: 0.45~1.42mm

Steel cutting Rule Height Range: 7~52mm

Control System: PLC

Power Supply: Single Phases220V,20A3KW,50/60Hz

Dimension & Weight of Rule Elevator: 700x900x1200 200KG

Send an appeal and we will contact you as soon as possible!

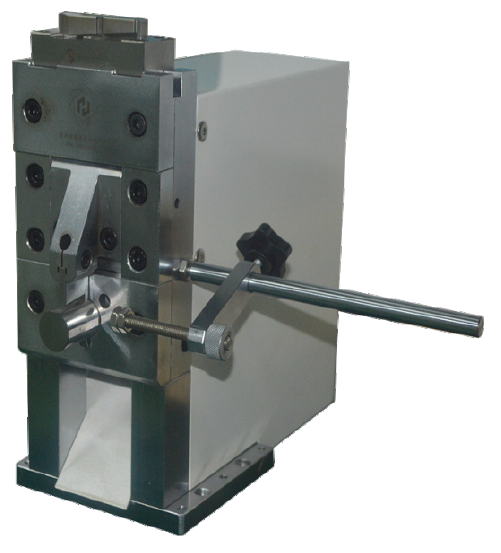

JH-LBS

Steel cutting Rule Thickness Range: 0.45~1.42mm

Steel cutting Rule Height Range: 7~40mm

Compressed Air Supply: 1CFM at 6bars

Dimension & Weight of Machine: 400x400x160mm 30KG

Send an appeal and we will contact you as soon as possible!

- DYHUA -

DHRM-550 Rubber cutting machine

Cutting speed: 7200MM/minute

Working area: 550mm*580mm

Machinable material: Rubber, sponge, etc.

Cutting thickness: Max to 25mm

Working way: CNC

Tool power: Pneumatic oscillating tool

File format: DXF, CF2

Power supply: Three phase 380V±5% 50/60HZ

Air consumption: 80L/minute

Air pressure Standard: 6.3KG

Features DHRM-550

Excellent oscillating tool (Germany), high quality and stable.

Only needs 1.5M*1.8M for operation.

High speed for rubber cutting. Only 17-20 minutes to cut 15boxes rubber.

Environment friendly. Without any pollution.

Low cost for the maintenance.

The standard power supply of machine is 3phase 380V±5%\50/60HZ. If customer local power doesn’t match, customer need to prepare transformer / voltage stabilizer, or request seller help to purchase.

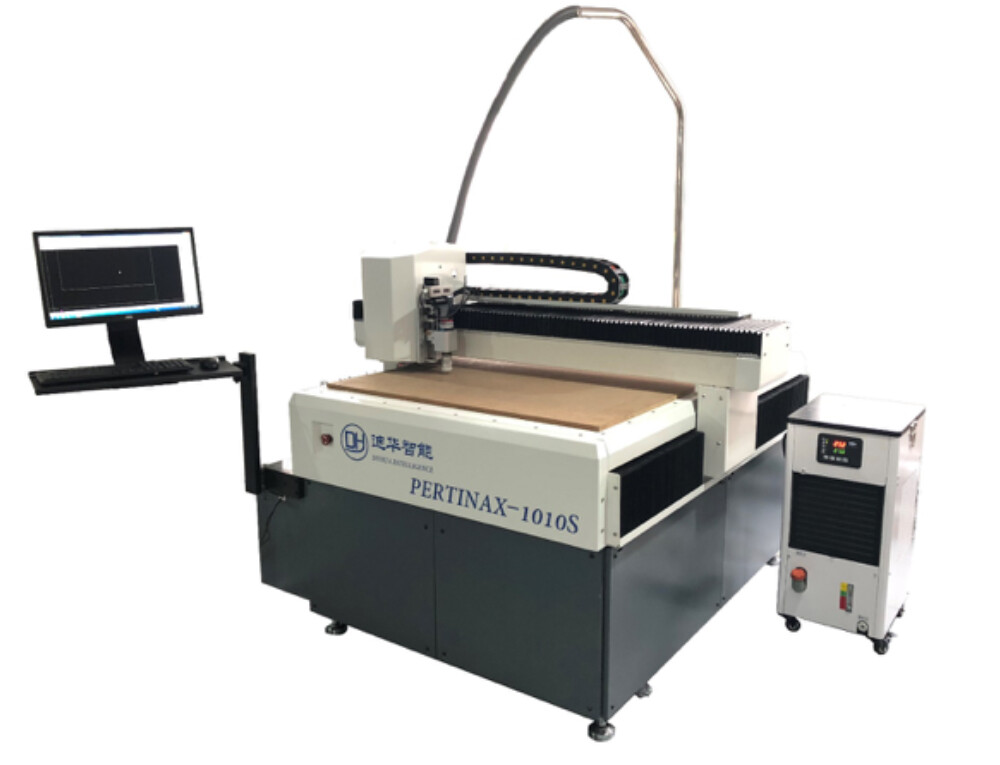

DYHUA PERTINAX-1010S-ZD Milling machine

Spindle speed: Rotating speed 1000-60000RPM

Spindle power: 1.5 KW

Cutting speed: 3000mm/min

Working area: 1060mm*1080mm

Cutting tolerance: ±0.03mm

Spindle tolerance: <0.005mm

Repeat tolerance: ±0.01mm

Tool tolerance: <0.005mm

File Format: DXF, CF2

Table height: 1.1m

Operate style: Follow-up & CNC

Power supply: Three phase 380V±5%\50/60HZ

FEATURES DYHUA PERTINAX-1010S-ZD

- We develop our own Pertinax counter making machine software, it can automatically generate creasing line according Dieboard figures before cutting.

- Equipped with 1.5KW auto change tool high speed spindle and 6 tools to slot, position hole, chamfer, cut off and mark. Our software automatically generates best paths to produce high quality and efficient products.

- Z-axis adopts exclusive design control mode, auto aligning instrument and follow-up processing way. Computer adjust the depth to ensure the operation simplicity and steady slotting depth. It can effectively avoid the depth control difficulties of other control methods and reduce the problems caused by materials.

- Oscillating tool option for cutting rubber function.

- High efficiently vacuum design to keep the surface clean.

- Complete machine hardware interlock protection, preventing from the wrong signals to damage spindle.

DH-FLS-2512 Laser cutting machine

Working area: 1240mm*2450mm

Laser path: Fixed laser line path

Drive mode: Servo motor high precision grounded ball screw

Power supply: Three phase 380V±5%\50/60HZ

File format: Support PLT, DXF, CF2

Laser power: 1000W~2000W

Location tolerance: ±0.02mm

Repeat tolerance: <0.02mm

Operating mode: Follow-up&CNC

Control system: German PA8000 digital laser control system

FEATURES DH-FLS-2512

- Fixed laser light path cutting mode to guarantee the same cutting gap.

- At least one year no reduction for the laser power.

- Less maintenance cost, CP laser source uses Turbo Blower to ensure no pollution of laser generator.

- Eight directions optical path compensation to ensure precision.

- Good quality and thick enough machine bed to ensure precision after long time use.

- Imported high precision grounded ball screw, high precision hardware, our software increase the screw pitch compensation.

- The cutting head adopts electronic follow-up to guarantee the same of cutting gap.

- Independent circuit case and airproof grade IP54 to reduce the damage of circuit from the smoke and dust.

- Germany digital control system, dedicated control functions of laser cutting to produce high speed, high precision and high stabilization perfect laser cutting gap.

- Create a less smoke and dust working environment with the strongly smoke and dust control system.

Gas specifications from CP laser source:

| Type | Purity | Rate | Consumption |

| He | 99.999% | 67.7% | 13.4-46.8 L/Hour |

| Co2 | 99.995% | 4.1% | 0.9-3.0 L/Hour |

| N2 | 99.999% | 28.2% | 5.8-20.2 L/Hour |

| O2 | Without oil and water. | ||

About JuhoBend

Shenzhen Juho Automation Technology Co., Ltd. is specialized in automation equipment and system development, manufacturing, sales and service of technical enterprises.

Our technical team ten years constantly strive to become stronger in the field of industrial automation, enthusiastic perseverance, casting our today's technical strength. Juho science and technology involved in many areas, has been in the Die cutter, Optoelectronics, Advertising and other industries to follow the success of the follow-up process to launch a large number of equipment and systems.

Specific types of projects mainly involves: computer automated Bending, Automated processing, Automatic Assembly, Automatic Detection, automated mask / paste glue / labeling, automated Joint, automatic feeding, automatic welding and so on.

Industry application

Presentation

Заголовок окна

JUHO Auto Bending Machine

Presentation auto bending machines for biggest exhibition DRUPA 2021

Contact Us

BoxPro Engineering

Ganibu Dambis, 36, App. 413

Riga, LV-1005, Latvia

Phone: +7 921 938 00 67

Pavlov Sergei

E-mail: sale@juhobend.com

Distributor in Italy:

For Box Srl

Via A. Grandi 4/15

20068 Peschiera Borromeo (MI)

Tel. +39 02 49751167

Fax: +39 02 91473647

4

Send an appeal and we will contact you as soon as possible!

Политика конфиденциальности

Редактируемый текст

Данный сайт использует Cookie

Редактируемый текст